Resource use and circular economy

Our policy

Vion processes farm animals to produce high-quality protein products, aiming to contribute to the UN SDG 12 and to take responsibility in advancing a circular economy. We do this by focusing on the optimal utilisation of processed pigs and cattle, and valorisation of animal by-product waste streams from our meat production processes.

Our resource use and circular economy policy focuses on material outflows, specifically on the valorisation of animal by-product waste streams in accordance with Moerman’s ladder and the legislation surrounding by-products, as established by the Dutch Food Safety Authority.

How we classify animal by-products waste streams

The animal by-product waste resulting from the processing of pigs and cattle are divided into 3 categories based on the risks they pose:

Category 1 – Highest risk

Hazardous materials are incinerated to protect health.

Category 2 – High risk

High risk materials are not fit for human consumption.

Category 3 – Low risk

Low risk materials are recovered for circular use.

Our commitment to sustainable resource use

We are committed to embedding circular economy principles into our operations by maximising the use of animal by-products waste streams generated in our process. This approach is a cornerstone of our strategy to minimise resource outflows, avoid waste, and contribute to sustainable resource management.

Vion recognises the value of animal by-product waste materials and their potential to drive economic and environmental benefits when repurposed effectively. Sustainable processing of these waste materials is therefore essential to limit waste, maximise economic value, and comply with legal guidelines.

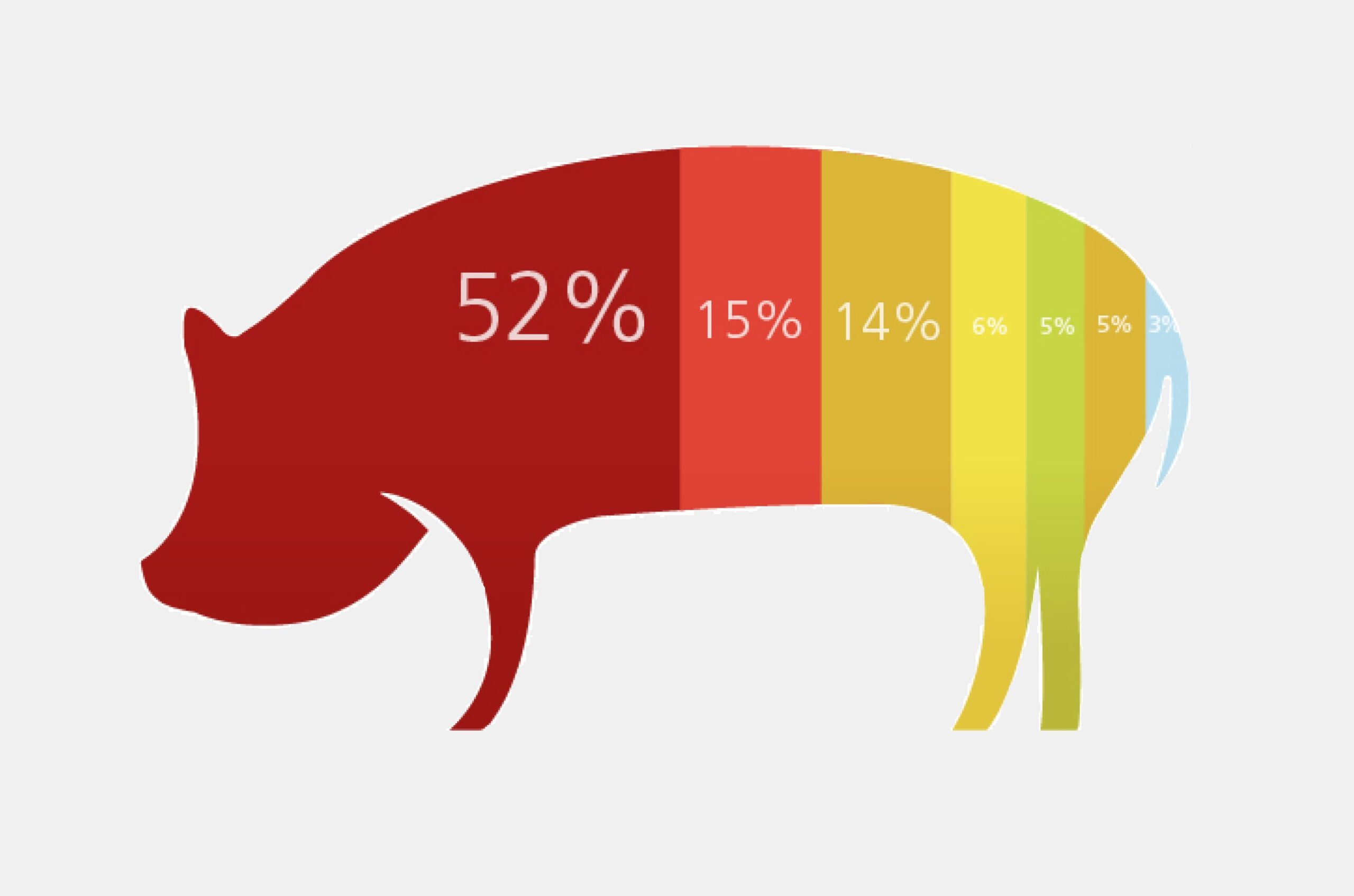

When processing a pig or a cow there will be a certain percentage of hazardous waste (category 1 and 2) and non-hazardous waste (category 3). All waste that does not end up in a landfill or is incinerated is defined as recoverable waste in Vion’s operations.

Our policy is to minimise hazardous waste per processed animal while maximising recovery into the circular production chain.

Our policy is to minimise waste per processed animal while maximising recovery into the circular production chain

Nieuws & Stories

Actions

We are committed to embedding sustainability into every step of our production chain. Here’s how:

Innovating manure processing: The NURTURE project

We are partners with Wageningen University & Research (WUR) on the NURTURE project, aimed at enhancing sustainability in manure treatment and the broader agricultural sector. The project focuses on converting a mixture of manure and sawdust into cellulose nano fibers and liquid fertilizer. The potential for on-site processing would allow Vion to manage manure and sawdust locally which not only reduces transportation emissions and logistical costs, but also the reliance on external suppliers and hence making the process more energy and cost efficient.

Reducing waste and enhancing efficiency

Total waste reduction is executed by benchmarking production sites to identify and implement best practices. This process involves tracking key KPIs and product quality across all locations. Improvements are evident in 2025 data versus 2024. Waste levels also vary by animal type; sows and retired cattle generate more waste than slaughtered pigs and young bulls. Additionally, Vion collaborate on innovative circular economy projects with universities, research institutes, and industry partners, supporting the development of waste reduction and resource optimisation solutions.

Valorising animal by-products

Through innovative strategies at our pig and cattle processing sites, we are identifying ways to transform by-products into valuable resources. By identifying these opportunities, we are effectively reducing the amount of waste that ends up in landfills and finding profitable, sustainable alternatives.

Improving practices across the supply chain

Our efforts to reduce waste produced per animal extends to our entire supply chain. We work closely with farmers to improve production practices and identify innovations. Through these collaborations, we have introduced strategies to optimise the feed withdrawal period before slaughter which reduces intestinal content in carcasses (and hence waste), improving product hygiene and quality. Furthermore, we convert immature manure into biofuels, hence contributing to a circular energy model.

We embed sustainability at every step of our production chain, from manure processing to waste reduction and resource optimisation

Nieuws & Stories

Targets

Our 2030 vision

In 2024, Vion began collecting total waste data per processed animal at its pig and cattle processing plants. Metrics focus on category 1, 2, and 3 animal by-product waste streams and the number of animals processed at pig plants (Boxtel, Apeldoorn, Groenlo) and beef plants (Tilburg, Furth im Wald). As part of its sustainability strategy, Vion has set 2030 targets for waste reduction and recovery to support upcycling and circular practices. For pigs, the goal is under 18 kg of waste per animal, with over 86% recovered and less than 14% hazardous. For cattle, the target is under 185 kg per animal, with over 63% recovered. The base year is 2024.

We are currently working to reduce waste and maximise by-product recovery, creating a truly circular value chain.